Your All-in-One Mega Resource

- Design & Structural Considerations

- Structural Frame vs. Open Web Trusses

- Proprietary Installation Process

- Attaching the Fabric

- Endwall Design

- Materials Used

- Collateral Loads on the Structure

- Hanging Loads on the Structure

- Sidewall Commodity Loads

- Environmental Loads

- Thermal Factors

- Use & Occupancy

- For Every Industry

Benefits of Tension Fabric

Properly engineered and constructed, fabric cladding has an extended life span in contrast to metal cladding. The proper steel finishes can continue to extend the life of your investment, but it’s more than just longevity the material’s properties bring to each project it influences.

Natural Light

Earth’s oldest energy source—the sun—is leveraged just right. White fabric cladding has natural translucency of up to 12%, allowing sunlight to flood into your structure. Using natural light has several advantages in fabric buildings over trying to brighten a dark building with artificial lighting, the most desirable being cost savings as fewer lights are needed in the building.

Conductivity

Fabric also has non‐conductive properties, meaning it doesn’t transfer heat or cold like other materials, such as steel or concrete. The inside of a tension fabric building, even an uninsulated one, feels cooler on hot days and warmer on cold days.

Corrosion-Resistant

Fabric is naturally inert to corrosion. This makes these buildings especially popular for customers storing corrosive materials, including salt, fertilizer, and mining chemicals. Steel frames need to be protected when storing materials that have corrosive properties, and Legacy’s epoxy-coated steel offers better corrosion protection than hot-dipped galvanizing.

Strength & Resilience

The proprietary fabric we use, ExxoTec™, is so tough, we can install our structures in Florida, the Andes Mountains, and northern Alberta. It’s more resistant to sun over the long run and much stronger than polyethylene. In fact, it’s so tough, we offer warranties on all our fabric cladding.

Fabric—to Shelter

Exclusively available through Legacy Building Solutions, our ExxoTec™ PVC fabrics provide significantly better strength and performance characteristics than PE fabrics. ExxoTec™ fabric offers our customers 28 oz. and 19 oz. PVC industrial fabric with high tensile strength and long-term weathering. The advantages of a tension fabric building over a clearspan metal building include natural light, fast installation, and greater ROI. The unique building materials include ExxoTec™ PVC fabric, a patented attachment system, and end-to-end construction management.

By combining the best elements of fabric buildings with the proven benefits of steel, we changed the game in quality, safety, and customizability. Legacy Building Solutions designs, engineers, manufactures, and installs every fabric building to meet building code requirements and customer specifications.

All Legacy Fabric Structures Have a Solid Steel Frame Made of Fabricated Tapered I-Beams.

Steel frames and secondary members are manufactured on-site using ISO 9001:2015 certified processes. Structural integrity starts with quality steel, so Legacy utilizes 55 ksi steel for steel framing members and small components. We install solid steel frames, using beams of a thickness appropriate to the structure.

By combining the best elements of tension fabric buildings with the proven benefits of steel, we changed the game in quality, safety, and customizability. Legacy Building Solutions designs, engineers, manufactures, and installs every fabric building to meet building code requirements and customer specifications.

Design & Structural Considerations

Every design choice can affect material requirements for strength and durability. Knowing your options is key to the success of your design and the lifespan of your building. To construct a long-lasting fabric structure, all materials must be carefully chosen for quality and durability. Taking account of fabric building structural factors makes a big difference in building longevity.

Legacy Building Solutions designs and builds tension fabric structures to fit your specific needs, ensuring longevity, safety, and functionality. We take into account every detail of the structure’s purpose, daily use, environmental factors, and building code requirements. Our fabric building design criteria ensure your fabric structure is optimized to maximize efficiency and your return on investment.

Structural Frame vs. Open Web Trusses

Legacy Building Solutions uses structural steel frames for all its fabric buildings. We use a solid steel frame, rather than the open web trusses used by many fabric structure manufacturers.

The Problem with Open Web Trusses

One type of structural failure when framing a building with web trusses is “chord plastification.” This happens when a thin steel web within the truss “punches” through the wall of the supporting web frame, eventually leading to instability or structural failure.

Moreover, the hollow nature of the tubes makes them vulnerable to internal corrosion in caustic environments. Often this corrosion stays hidden inside the frame until it's too late.

Solid Steel Beams or Hollow Web Trusses?

Legacy uses solid steel I-beam frames. This makes a significant difference over web trusses in terms of building integrity.

Strength—Steel Offers Other Advantages

- Design Flexibility: Rigid steel frames use proven engineering principles for more design options.

- Clearspan Space: Solid steel frames create interiors that don’t require central support columns, giving the building owner an unobstructed floor space great for loading and unloading.

- Support for Options: Our frames can be engineered to support cranes, conveyors, catwalks, mezzanines, scoreboards, goal post, and HVAC systems.

Proprietary Installation Process

We are committed to a seamless install with our experienced install crews. We have incorporated some amazing innovations into our buildings, and it takes a very experienced crew to get it right. To further reinforce our steel frame designs, Legacy includes secondary framing practices that add to the strength and lifespan of our fabric buildings.

- Purlins

- Flange Braces

- Cross Cables and Bracing Rods

Attaching the Fabric

Individual Bay Panels

Unlike a mono cover fabric building, all Legacy buildings are constructed with individual roof and wall panels. Roof panels, typically 20 feet wide, are attached to the frame via a keder rail. Fabric panels are double layered in any area where they contact steel.

With fabric cladding, getting the tension correct for wall panels and roof panels is very important. Many fabric structures require retensioning of the exterior fabric cladding a number of times over the life of the building. We use a process—a patented process—of tensioning at installation so your building will not need retensioning.

That’s good for you, but it’s also good for the longevity of the building. If fabric moves around on the frame, due to incorrect tensioning, the friction on the steel frame causes the fabric to wear out. Then you may need to replace the entire exterior. Our fabric panels stay where we put them, and that adds to the overall durability of the structure.

Endwall Design

Endwall fabric has a critical impact on the longevity, functionality, and appearance of the building.

Fabric Attachment

Every endwall features our patented keder attachment system. Endwall fabric is tensioned vertically and horizontally and supported by girts. Fabric panels in the endwall are double-reinforced in all areas where they touch steel frame members.

Reinforced Structural HSS Columns

HSS endwall columns provide strength at 46 ksi while minimizing the need for lateral bracing.

Materials Used

Steel

Our durable steel frames feature 55 ksi steel welded by our own highly skilled and certified welders. Steel frames are available in hot-dip galvanized, primed, or painted. For corrosive environments, Legacy Building Solutions’ exclusive EpoxxiShield™ finish provides the highest level of corrosion resistance and protection. Our frame finish packages range from a single coat of two-component polyamide epoxy paint for basic applications to a three-coat option for the ultimate in corrosion protection.

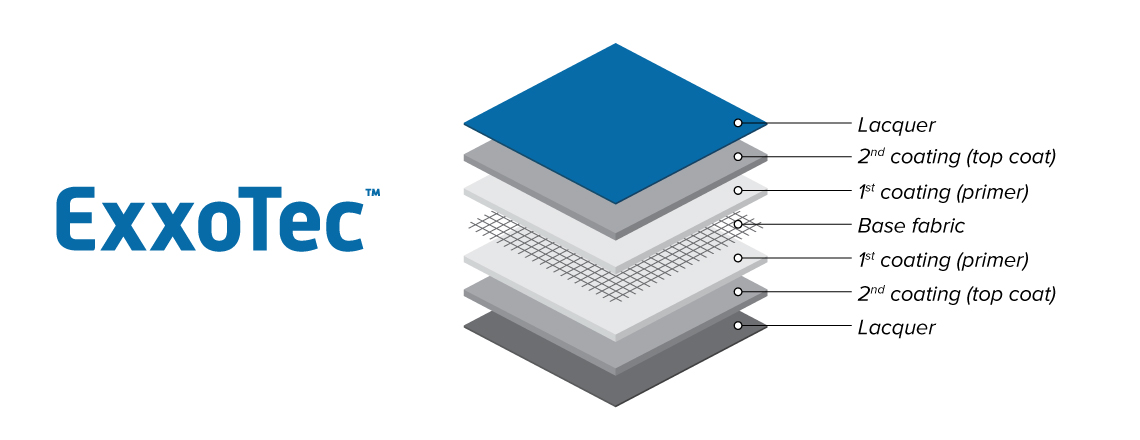

Fabric

Legacy’s premier fabric is ExxoTec™, a PVC fabric with superior strength and performance characteristics. ExxoTec™ is exclusively available through Legacy Building Solutions.

Collateral Loads on the Structure

A collateral load is additional weight applied to the frame from operational equipment such as cranes, conveyors, catwalks, etc. Our building and project design consultants work with you at the outset to determine what collateral loads will be included in the design, as well as building code regulations.

Typical collateral loads include:

- Indoor Lighting

- Sprinklers and Fire Suppression Systems

- Heating, Ventilation, and Air Conditioning Systems (HVAC)

Hanging Loads on the Structure

Additional loads supported by the structure’s frames are calculated into the roof-load specifications of your fabric structure. During the fabric building design process, we balance hanging loads with all other structural factors to ensure the appropriate reinforcement is engineered into the frame and foundation.

Common hanging loads include:

- Conveyor Systems

- Overhead Cranes

- Mezzanines and Catwalks

Sidewall Commodity Loads

Bulk commodity and other storage buildings, we recommend pre-cast or cast-in-place (CIP) concrete walls. Pre-cast walls provide flexible and adaptable walls that are perfect for the increasingly popular flat storage or bulk materials. Cast-in-place concrete walls have a high load-bearing capacity, allowing bulk piles to extend to the very edges of the building. Whether you chose pre-cast or cast-in-place, Legacy can easily accommodate into the design of your fabric building.

Environmental Loads

Legacy designs and builds structures to withstand environmental factors, such as:

- Seismic Loads

- Wind Loads

- Snow Loads

Thermal Factors

The heating and cooling requirements of a fabric building can also affect the overall frame design. For instance, if you plan to heat the interior of your fabric building, the heating system and insulation must be considered in the material specifications.

Use & Occupancy

Occupancy factors become particularly important in fabric structures intended for public use. Building codes include a “hazard rating” or “importance category” that relates directly to the maximum use and occupancy that the building is expected to receive. Legacy specializes in designing and constructing long-lasting buildings that meet or exceed all local, and sometimes international, building codes.

Plain and simple? Our ability to design to local building codes is a distinct advantage of working with Legacy.

For Every Industry

As a leading tension fabric structure manufacturer, we know the importance of a detail-oriented approach. Every aspect of the building is customized for maximum efficiency. Legacy’s process is designed around creating safer, higher-quality buildings that align with our customers’ objectives and work within any industry application.

Benefits of our custom fabric building system include:

- Exclusive ExxoTec™ PVC fabric

- Customized building sizes for the exact width (to over 300 feet), length, and height required for your specific application

- Clearspan building design

- Flexibility to apply fabric on the roof and conventional materials (brick, stone, wood, steel, masonry) on the sidewalls

Application in Industries

Our buildings have a few common denominators from project to project and industry to industry. One—all buildings are built with the intention to protect—a literal roof over the heads of our customers. That’s first and foremost for a reason.

Two—our structures are built on proven engineering. With the quality of industrial fabrics always improving, we knew we could create a durable, quality building that would not only last decades, but would be equal to, or better than, existing traditional structures built of steel or wood or bricks.

Our Process

Whether you have a complete building spec or just an idea in mind, our team will lead you through the design process with expertise and efficiency.

Our in-house engineering team leads the charge on creative solutions that benefit all project stakeholders—namely you.

Legacy is an end-to-end manufacturer, meaning your project will be built right on-site in our 87,000 sq ft facility in Central MN.

Now to the good stuff. We typically use our own Legacy crews for the install. They have a reputation for a strong work ethic, strict safety practices, and deep knowledge of how our structures work. They also are trained in our proprietary cladding attachment process.

Get a Quote from Legacy

More Tension & Less Stress

Building projects with Legacy Building Solutions means creating custom engineered fabric buildings based on your project’s specifications. Together, we’ll create the ideal building to meet your requirements while eliminating excess square footage, increasing energy efficiency, and resulting in a faster return on your investment.