ExxoTec™ Fabric - The Next Level of Toughness

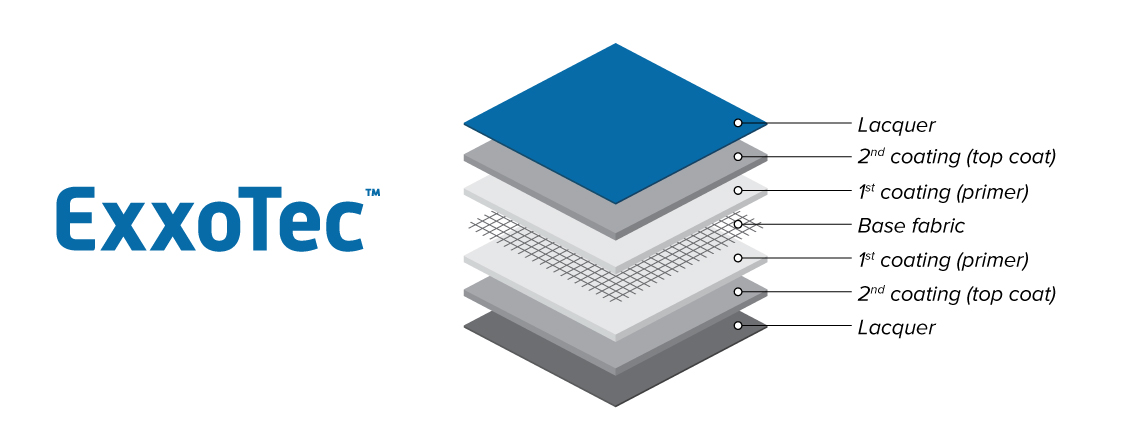

Legacy’s preferred building material is our exclusive ExxoTec™ PVC fabric. Using ExxoTec™ helps our customers receive the best value in the fabric building industry, along with the service and commitment Legacy is known for. This tension fabric structure membrane is built to withstand harsh weather conditions for superior longevity. What’s more, with a fabric building skin from Legacy, you can be sure your structure will feature the aesthetic appeal you’re looking for. See what makes our fabric tension membrane buildings an ideal choice for a wide range of applications.

ExxoTec™ is a premium PVC fabric with significantly better strength and performance charactersitics - available at a highly competitive price. ExxoTec™ fabric is exclusive to Legacy Building Solutions and available in 28 oz. ExxoTec™ Elite and 19 oz. ExxoTec™Pro.