This is Why We Exist: to Add Clarity, Confidence, & Capability to Any Project You Imagine

The art of building is an investment and a direct, visible reflection of our customers. That’s why Legacy Building Solutions does what we do—builds custom tension fabric buildings that surpass expectations, achieve the highest standards of safety, and last for decades. We were built for this—learn how everything we do, from our proprietary installation process, exclusive EpoxxiShield™ frame finishes, and ExxoTec™ fabric cladding, and incredible team supports your next project.

Our Process

Our team meets with yours to establish a final goal for your building.

We assist with bid/RFQ requirements to clarify your specs and timeline.

Your vision begins to emerge in a Rough Order of Magnitude (ROM) we design.

Design phase is complete, covering every last detail of your project’s scope.

Thorough site evaluation and pre-construction planning occur before groundbreaking.

Our team—composed of experienced Legacy craftsmen—gets down to work.

All Industries

Automotive

Aviation

Bulk Commodity

Equestrian

Livestock Farming

Military

Mining

Oil, Gas, & Energy

Ports & Waterways

Sports & Recreation

State & Municipal

Waste & Recycling

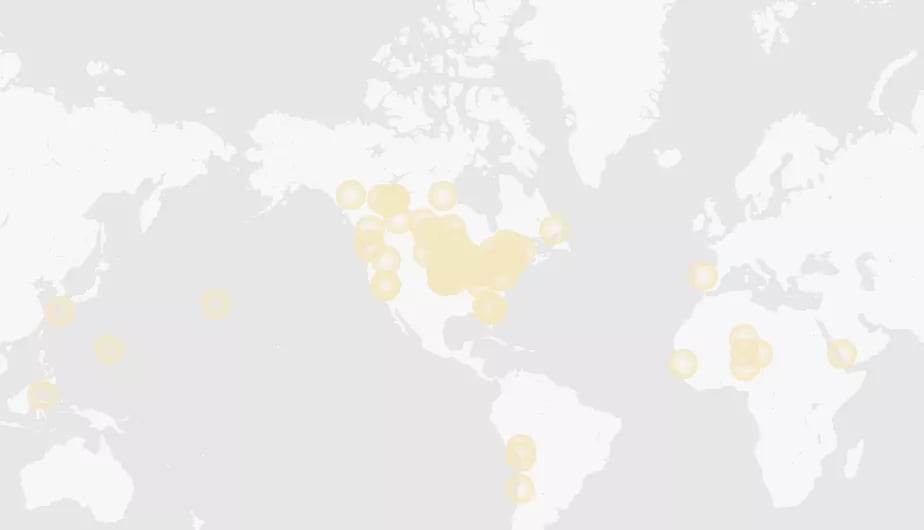

Project Map

The map above is a small representation of the projects that Legacy has worked on.

151+ Locations

There are no two builds alike. Legacy buildings cover every imaginable landscape, from the toughest terrains to the most exacting geographical constraints.

830 Buildings

Undeniable global presence with projects currently executed in six separate locations around the world including North and South America, as well as recent buildings in Europe, Africa, and the Pacific Rim.

We've Got You Covered

Legacy has a reputation for being forward-thinking, innovation pushing, and a leader in excellence. We share our stories and principles to highlight safety and the best building practices in our industry regularly. Stay in the know by subscribing to any combination of our efforts.